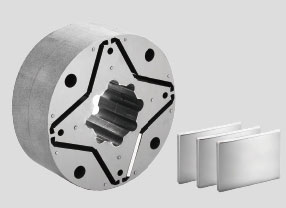

A new generation of imported hosts

- Advanced spiral tooth shape technology

- New 5:6 asymmetric rotor tooth shape

- Drawing letiz high-precision coordinate measuring machine,

- Adopt quality SKF tapered roller bearings imported from Sweden

- Relative power compared with ordinary models, the displacement increases by more than 5%-10%

Permanent magnet machine

- Reasonable structure, high power density;

- The inertia of the rotor is very small and the response speed is very fast.

- Ultra-high intrinsic coercive rare earth permanent magnet material, strong anti-demagnetization ability;

- Constant torque output is available within the range of gambling and rated speed;

- Special asymmetrical magnetic circuit design makes low speed torque ripple small;

- High balance accuracy, stable high-speed operation, low noise, low vibration;

- Fully sealed or high protection grade shape structure design;

SKF bearing

SKF bearing is the world leader in bearing technology and manufacturing, and is committed to the research and development of the bearing industry, and is the first brand of direct bearings. Compared with other product bearings, it has good wear resistance, excellent fatigue resistance, strong corrosion resistance, and comfortable silence, which makes the permanent magnet synchronous non-inductive motor have longer life, higher reliability and lower noise.

Magnetic steel for permanent magnet motor

The high performance and low loss silicon steel sheet is used for stamping, and the mechanical strength is simulated and analyzed by finite element method to ensure sufficient mechanical stiffness and mechanical strength and minimize the inertia of the rotor. The rotor magnet uses high-performance Ndfeb permanent magnet material to form a sine-wave air gap magnetic field. Do not laugh at the Kun key to increase the quantity of the product and the key boat requirements.

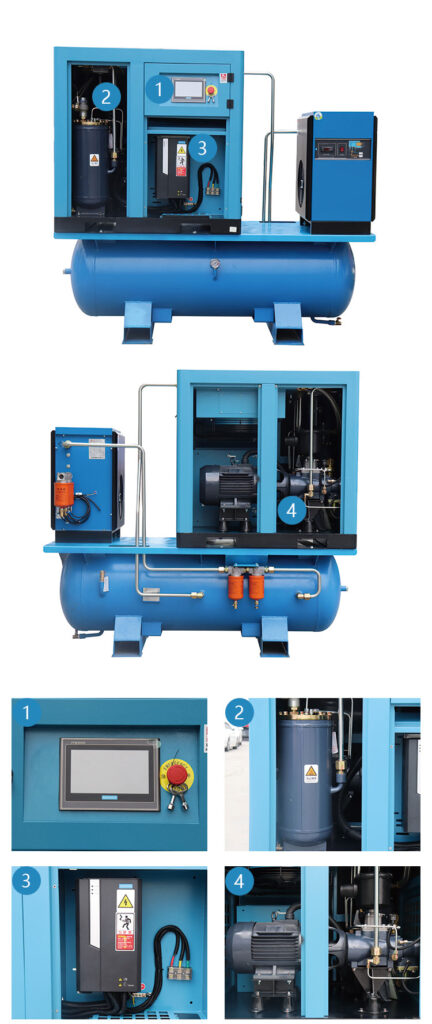

Energy saving filtration system

Efficient oil and gas separator, special simplified design, aggregate separation core and oil return device composition, service life of 6000 hours, oil filter, low pressure drop design, service life of up to 4000 hours, high filtration accuracy effectively protect the bearing and screw machine rotor. Air filter, filtration does not need to change the direction of air flow, directly through the filter media, reduce pressure loss, more energy saving than the traditional air filter, filter area, higher precision, longer life.

Designed cooling system

The use of high-efficiency warp-type large heat exchange area cooler, heat exchange surplus 30%, better cooling effect, can work at an ambient temperature of 45℃.

Energy saving intake control system

Specialized design of the new integrated air intake valve, air intake adjustment range 0-100%, capacitive valve adjustment, pressure loss is small, stable action, long life, the key parts of the air intake valve solenoid valve with international well-known brands, to ensure the absolute operation of the screw compressor safety and economic control.

Pressure valve

- The pressure valve has the function of check, the seal is FKM or PTFE, the check is sensitive and the seal is reliable;

- The pressure valve spring is strengthened, not easy to deform, P fatigue, stable opening pressure;

- Diversified installation and connection methods, convenient installation and maintenance.

Intelligent microcomputer control system

- Chinese (English) text display, touch button, menu operation intuitive fast, convenient;

- It can preset and control the star triangle transformation, start, load, stop, overpressure and other delay time during operation.

- Can display and deal with various on-site faults;

- The type and occurrence time of historical faults can be stored and queried

- Has an internal calendar, can be long-term accurate travel time and can be modified:

- It can accumulate and store the running time, loading time, load reduction time, and the use time of various filters for long-term storage.

Laser cutting special permanent magnet frequency conversion 50GS

certified by

Precision meets power with our Laser Cutting Special Permanent Magnet Frequency Conversion – engineered for unmatched accuracy, efficiency, and performance in every cut.

Packaging and delivery

Packaging: Pallet

Port: Shanghai

Place of Origin: China

Supplying

GET IN TOUCH

Company:

Suzhou Flute New material Co.,Ltd

Factory Address:

1099 Yunli Road, Wujiang District, Suzhou City, Jiangsu Province

Contact Numbers:

0086-18751866536

Contact Person:

Lemon