Core technology, ingenuity design!

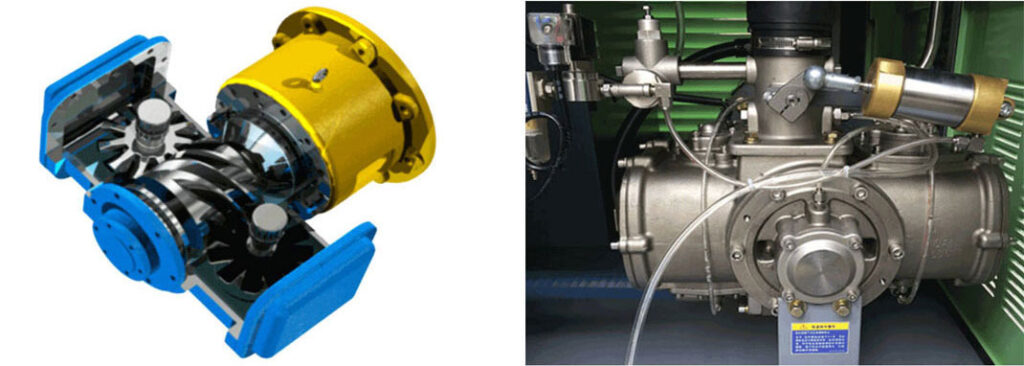

The shell, star wheel and rotor of the main engine are made of stainless steel and special alloy materials, and are added by a special CNC machine Manufactured to ensure that the core components run without scaling and rust.

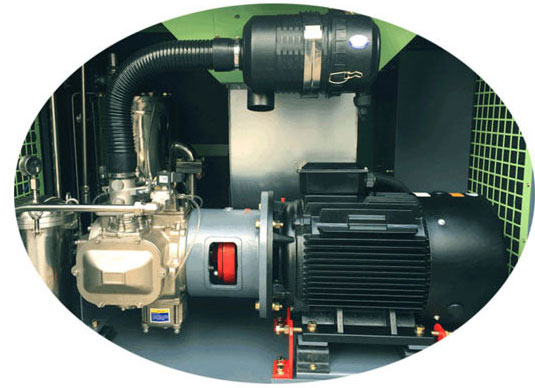

Compared with traditional dry two-stage compression, water-lubricated single-stage compression has a good innate advantage The more it is, the two major characteristics of low temperature compression and low speed operation, its high volumetry efficiency and durable service life Is the return to the user; The use of water for lubrication in operation will greatly reduce the user’s operating costs: no oil The environment is the guarantee of gas supply quality!

Highlight the difference, create a mystery!

The whole system is composed of stainless steel parts and control parts in line with food grade standards, including: compression host, water and gas separation tank, control valve, circulation pipeline, connector, filter parts, water level controller, water supply and drainage device, system hose and other corrosion-resistant material components to ensure the absolute purity of the system.

Humanistic design heart action--------A smart, energy-saving, stable, safe!

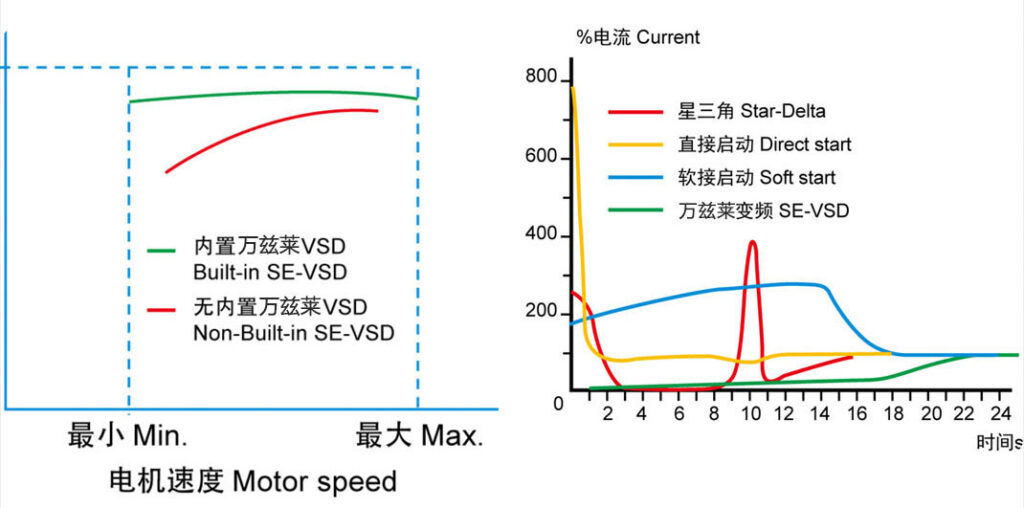

The whole series adopts frequency conversion speed regulation technology, the speed is stepless adjustment, the pressure is stable, and the start is smooth, so that the power of the gas changes with it, and the energy is effectively used.

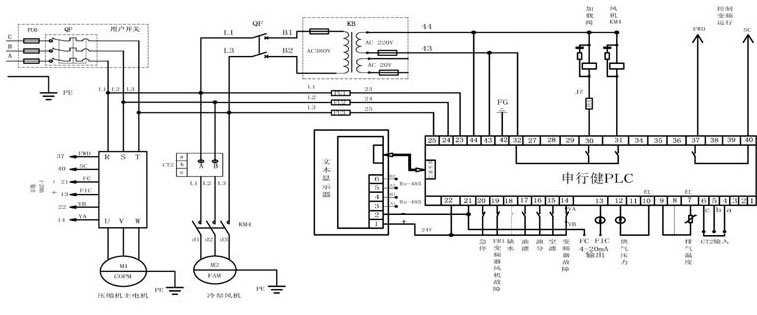

Equipped with microcomputer intelligent control and water supply softening system to ensure that the circulating water does not form scale, so that the lubrication, sealing and cooling functions are better played; Automatic control of water and electricity according to the needs of the system, automatic detection of the key points of the equipment protection set values, to achieve the stable operation of the whole machine and alarm protection of the complete function.

Soft water cycle economy environmental protection ----- pure water lubrication, oil-free guarantee!

Compared with traditional compression, dry compression, because there is no sealing medium, must pass through two stages of compression exhaust at high speed during operation. High speed will produce 200℃ high temperature, which will make the lubricating oil in the gearbox emit odor into the atmosphere and be inhaled by the compressor, which is difficult to ensure the purity of the discharged air. When water lubrication is compressed, water is used as the sealing medium, the running speed and temperature are very low, and there is no lubricating oil in the system, which can ensure that the discharged compressed air is clean and oil-free.

Core technology, ingenuity design!

After several years of careful research and experiments, successfully developed oil-free water lubricated air compressor host, its shell, star wheel and rotor are made of stainless steel and special alloy materials, processed by the temple CNC special machine, to ensure that the core components never scale and rust.

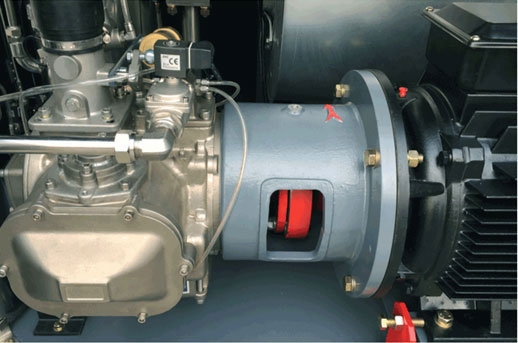

The main machine adopts a single screw structure, screw meshing the left and right star wheel plate compression, to ensure the mechanical balance under pressure, to achieve low vibration, low noise effect.

The structure is simple and durable ------ greatly reduces operation and maintenance costs!

Our water-lubricated oil-free air compressor achieves low temperature compression, low speed operation, simple structure and easy maintenance, thus greatly reducing maintenance costs. The dry air compressor due to high temperature, high-speed operation and other congenital defects, resulting in complex structural design, cumbersome maintenance, so that the operating cost is much higher than the water lubrication air compressor. Obviously, the advantages of water-lubricated air compressors are extremely obvious.

Pure water lubrication, economic and environmental protection!

When the air compressor is lubricated without oil and water, the water pipe is connected to the water softener, and the water filtered by the water softener is changed straight to the outlet valve or the excess water is discharged and connected to the system circulation. In places where tap water is difficult to reach, you can also directly use barreled purified water or distilled water (mineral water cannot be used). The specific heat capacity of water is much greater than that of oil, so that the circulation temperature of the whole system does not exceed 50 ° C, isothermal compression, higher efficiency, compressed gas oil content is zero, energy saving and environmental protection.

Energy saving and environmental protection, quality assurance!

The whole system is composed of stainless steel parts and control parts that meet food grade standards, including: compressor host, water and gas separation tank, control valve, circulation pipeline, connector, filter parts, water level controller, water supply and drainage device, system hose and other corrosion-resistant material parts to ensure the absolute purity of the system.

Humanistic design, heart in one!

The whole series of oil-free water lubricated air compressors will adopt frequency conversion speed regulation technology, speed stepless adjustment, pressure stability, smooth start, to achieve the change of gas power changes, to achieve the effective use of energy.

Equipped with microcomputer intelligent control and water supply softening system to ensure that the circulating water does not form scale, so that the lubrication sealing and cooling functions are better played; Automatically according to the needs of the system to control the water, electric action automatic detection equipment key points of the protection set value to achieve the stability of the whole machine and alarm protection function.

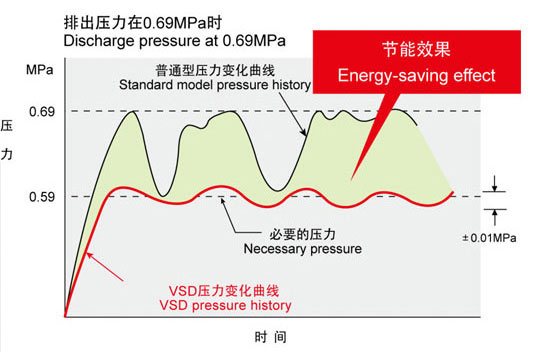

Principle of variable frequency speed regulation

VSD inverter is a new concept product that adjusts and controls the speed of the compressor drive motor according to the actual gas consumption change, so that the actual power changes and energy is effectively saved. The product uses electronic frequency conversion system, accurate gas consumption matching and accurate pressure control technology not only directly achieve energy saving effect, but also bring stability of pipe network pressure and eliminate the peak current at the start of many benefits, providing a new energy saving and emission reduction program for modern enterprises

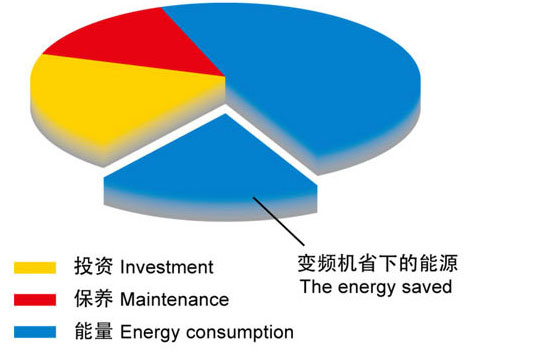

Energy conservation prediction and evaluation

In the entire working life of the air compressor, energy consumption does account for the majority of all costs. Therefore, before selection, carefully evaluate your actual gas use changes, and then decide on an investment plan to obtain a reasonable return on reasonable investment.

Steady pressure

PID(proportional gain, differential gain, integral gain) method is used to precisely adjust the speed of the air compressor, automatically track the change of the gas volume of the system, stabilize the system pressure, and reduce the power consumption.

No-peak current

Frequency conversion start-up greatly reduces the impact of the air compressor on the power grid and mechanical parts, eliminates the peak current during start-up, and extends the service life of the parts.

Oil-water free permanent magnet variable frequency air compressor WZS-15VF/W

certified by

Experience pure performance with our Oil-Free Water-Lubricated Permanent Magnet Variable Frequency Air Compressor – the ultimate solution for clean, efficient, and reliable compression.

Packaging and delivery

Packaging: Pallet

Port: Shanghai

Place of Origin: China

Supplying

GET IN TOUCH

Company:

Suzhou Flute New material Co.,Ltd

Factory Address:

1099 Yunli Road, Wujiang District, Suzhou City, Jiangsu Province

Contact Numbers:

0086-18751866536

Contact Person:

Lemon